Greenland's Kvanefjeld: ~90,000 t of Radioactive Waste?; Rare Earth Exchanges; China RE Imports from Myanmar back?; Russia goes Phosphogypsum; Pea Ridge; UUUU and Chemours; Neo's results and the lot.

Rare Earth 21 March 2025 #171

Note

The PDAC hangover has passed. This is a really long post, which does not do justice to everything that is happening. Some sources suggest that China’s dominance of rare earths may end within the coming 10 years.

Comment period for proposed regulation in China ended

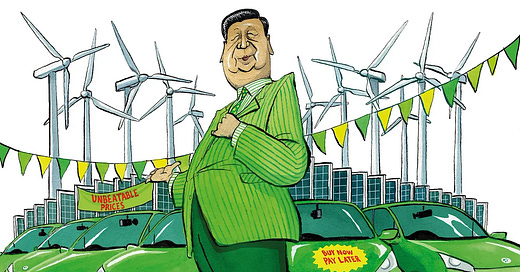

If implemented as is, China’s government will have full control over all China’s rare earth production. No more uncontrolled imports of raw material. China can also choose to only produce for its own needs, reducing exports to long-standing numerical targets. With the cerium imbalance problem heading for a solution, only lanthanum is pending.

Japan would be most affected and obviously fully understands the situation. Hence the published intention to go ahead with Minami Torishima deep sea mining.

Western junior rare earth miners will need to cough up serious marketing concepts, as shipping to China may no longer be a default option. If they read The Rare Earth Observer, then it should have long dawned on them what big challenge this is. We are here to help.

Greenland

In this issue we look at the last remaining Greenland rare earth case. We went through 17 years of corporate announcements and publications. We also re-visited data of the EU projects from a decade ago for a deeper look. We were not amused about the findings and massaged results.

Ukraine

For the past 15 years, systematic geological work has not been financed from the state budget in Ukraine.

Departing from earlier pointing at somewhat explored apatite deposits of low to lowest rare earth content Ukraine is now spreading information about what is best described as occurrences and Russian controlled Azov Sea beach sand monazite. In a TSN interview Stella Shekhunova, director of the Institute of Geological Sciences of the National Academy of Sciences of Ukraine, describes the the situation like this:

“Most of our promising objects are still only a potential opportunity to obtain "metal" . A promising object, as a rule, will still need to be thoroughly explored, the economic feasibility of development assessed, and production organised.”

There are several maps of Ukraine circulating in the media, detailing locations of supposed rare earth deposits. All of these maps look different, all of them said to be basing on Ukrainian sources.

Europe is full of “potential opportunities.” If you lower your expectations deep enough, you could also mine tiny rare earth deposits in tiny Slovakia.

United States

The daily news from Washington DC suggest that the current U.S. administration is not “crossing the river by touching the stones (摸着石头过河)” but rather “jumping into the deep end.”

The executive order regarding rare earth projects is such a jump. Unrestrained optimists suggest the current U.S. administration has a plan, a secret sauce for rare earth.

There is an apparent, persistent threat that China may continue in selectively cutting supplies of individual products to the U.S. However, the U.S. should take great care in assessing that there is a per-product existing domestic market with existing value chains, as well the real current and foreseeable future demand. This is absolutely necessary in order not to waste taxpayer funds on still-born initiatives - or fall victim to snake-oil salesmen.

Hedging Rare Earths

Some western companies sign agreements with rare earth hopefuls for products which they actually can’t use, in order to hedge rare earth price risks. Automotive companies have no use for mixed rare earth carbonates or oxides. The hedge makes also no sense in complete absence of product standards and lack of liquid markets for the hedged products in the West. So we take a look at rare earth commodity exchanges in China.

Trump to Expand Critical Mineral Output Using Wartime Powers

An executive order signed by the president Thursday taps the Defense Production Act as part of an effort to provide financing, loans and other investment support to domestically process critical minerals and rare earth elements, according to a White House official. The US International Development Finance Corporation, working with the Department of Defense, will provide financing for new mineral production projects.

The order, which also encourages faster permitting for mining and processing projects and a directive for the Interior Department to prioritize mineral production on federal land, comes as a direct response to long-held concerns among the US and allies that China overwhelmingly controls the processing of some of the most important critical minerals.

Powering production of raw materials that don’t find a ready market in the U.S. is not such a good idea. Uncounted times we have pointed out, that this needs a methodical, structured approach.

Just throwing money and labour at the issue will not contribute to a solution of the problem. But this will only become evident after the current administration has long gone.

Kvanefjeld

Fearing toxic waste, Greenland ended uranium mining. Now, they could be forced to restart - or pay $11bn

The range is home to one of the largest undeveloped deposits of rare-earth minerals and uranium in the world: the Kvanefjeld site, or Kuannersuit in Greenlandic. It contains high concentrations of metals such as terbium and neodymium, which are used to manufacture permanent magnets in wind turbines and electric cars. Every major power in the world is scrambling to get access to these minerals for carbon-free energy and transport.

A proposed open-pit mine would be worth about $7.5bn (£6bn) if it went ahead, according to the site operator, generating income for the island’s economy.

The fear may be justified.

An extremely challenged project

First of all, the aversion of Greenlanders to anything radioactive can’t possibly have been a surprise to the operator of Kvanefjeld. It actually was the status quo already 17 years ago, when the operator started off with Kvanefjeld.

Lujavrite

A term, originally spelt luijaurite, for a melanocratic agpaitic variety of nepheline-syenite rich in eudialyte, arfvedsonite and aegirine with perthitic alkali feldspar or separate microcline and albite. A pronounced igneous lamination is characteristic, as is the abundance in minerals rich in incompatible elements such as the REE, U, Th, Li etc. (mindat.org)

Kvanefjelds rare earth bearing resource rests in the silicate mineral lujavrite and, within lujavrite, steensrupine is the main host of rare earths and uranium. It is not exactly the easiest resource to work with and at times the operator of Kvanefjeld is said to have employed 4 geologists simultaneously for dealing with it.

An early flow chart designed for Kvanefjeld’s “prefeasibility study” (PFS) showed a striking similarity to a flow chart that originally had been designed by another rare earth hopeful for another extremely challenged rare earth resource elsewhere. This flowchart seemingly was abandoned after the PFS because it was technically not working for Kvanefjeld, according to the provider of the original flowchart.

The adventurous PFS demonstrated, that the project would consume power 16% of Greenland’s current power production. Other curiosities include millions of dollars per year being spent on “FIFO,” fly-in, fly-out staff.

The PFS also says clearly that at depth the rare earth carrying mineral is largely eudialyte and the PFS identifies this eudialyte as technically and economically non-feasible (the operator of Norra Kärr, Sweden, insists that it is feasible…). The feasibility study of 2015 says:

Economic REE and uranium grades occur in the uppermost sections of the lujavrites…Grades begin to decrease below 200 m from ground surface.

It remains unclear, though, if the deemed non-feasible eudialyte had become part of the resource assessment quantity or not.

The 2015 Feasibility Study

It is not clear from the operator’s executive summary of the FS, who authored the FS. We assume SRK Consulting. If so, we would have expected to find a disclaimer regarding the processing contents of the FS.

Kvanefjeld’s target intermediate product “CMREO” is all rare earth elements after praseodymium until lutetium, plus lanthanum and cerium by-products:

This is the 2015 feasibility study flowsheet:

In other words, the low-value lanthanum and cerium goes one way and all the remaining high value rare earths go to China - and they remain there, as also in 2015 toll-processing (=export processing) of rare earths was illegal in China (since 1998). It is inconceivable that management shouldn’t have known at the time.

The “Rare Earth Concentrate 15% REO” actually includes uranium. The FS says that the rare earth recovery rate of the processes in this diagram should be 79%.

And here this Rare Earth Concentrate 15% REO plus uranium goes further downstream:

The rare earth recovery rate after the above steps is supposed to be 70%. So, according to the FS, the overall ore to “Mixed REO Concentrate” (Pr to Lu) recovery rate is theoretically 63%.

Carbon hog

Environmentalists will absolutely love this one:

Power generation is provisionally based on use of heavy-fuel-oil fired multiple reciprocating machines. The heavy fuel oil power station is located at the concentrator site.

2015 feasibility study financials

That section of the FS is an attempted insult of every investor’s intelligence.

Like many other junior rare earth miners Kvanefjeld’s operator tried to prove feasibility based on prices of those finished rare earth products that the company wasn’t even planning to produce.

But after 10 years that is water under the bridge, so no need to dive into the details.

2015-2025

Over the past decade inflation has been an average of about 2.9% per year, so OPEX and CAPEX of the feasibility study will have to be adjusted at least 29% up, whereas Kvanefjelds rare earth “basket price” - on which the FS bases - is 44% lower at current rare earth prices. Projected revenue would need to be adjusted down accordingly, this time basing on the correct value of the target product, an intermediate, not some finished products’ prices.

The 2017 EURARE Project Result

The operator of Kvanefjeld enthusiastically participated in an EU-initiative called EURARE from 2014 to 2017. During the course of the now concluded EURARE project this was presented by the operator of Kvanefjeld:

“Dididium”? They meant Didymium. Didymium = NdPr. Beware of rare earth companies whose executives and directors don’t even know how to spell their own companies’ products. There are a couple of such highly qualified experts out there.

Recovery rate

The EURARE project reports:

In the Kvanefjeld deposit 3 t of the Kvanefjeld ore (with 1.3 % REO ) was mined and beneficiated at the GTK Pilot plant producing a mineral concentrate of 250 kg of 15% REO content .

The mineral concentrate of was then leached at the Outotec Pori Research Laboratories, Finland producing ~25 kilograms of mixed rare earth carbonate with 50% REO content [instead of 60% in a.m. material flow chart]

This was then processed by MEAB Chemie Technik GmbH, Aachen to produce separate streams of La/Ce, Nd/Pr, Y and HREE chloride fractions.

The company reported:

Overall approximately 250 kg of rare earth and uranium mineral concentrate was treated over a period of 250 hours. This stage of the refinery pilot plant operated from 31st of August until Friday the 11th of September.

Anyway, then lets look at the recovery rate:

Beneficiation: 3 t ore at 1.3% TREO (=39 kgs TREO) after more than 10 days of leaching turn to 250 kgs concentrate at 15% TREO (=37.5 kgs TREO): 96.15% recovery

Leaching: Mineral concentrate 250 kgs of 15% TREO (37.5 kgs TREO) produces ~25 kgs of MREC with 50% TREO (12.5 kgs TREO): 33.33% recovery.

Subtotal recovery rate 39 kgs TREO in ore to 12.5 kgs TREO in MREC: 32.05%

This recovery rate of 32% is even before the most difficult step, rare earth separation, where more recovery loss occurs.

This result is on a laboratory/pilot scale. On an industrial scale it can be worse.

In terms of the overall project, such low recovery rate typically kills the commercials. We have not seen any rare earth project being feasible based on a 32% recovery rate.

This recovery rate is half of the rate assessed by the 2015 feasibility study, curiously by the same companies and processes participating in both, the 2015 feasibility study and the EURARE project. A misunderstanding, perhaps?

Actual analysis results

“Separate streams of La/Ce, Nd/Pr, Y and HREE chloride fractions” sounds odd.

We have asked various participants of the EURARE project for the actual analysis results of the “separate streams of La/Ce, Nd/Pr, Y and HREE chloride fractions.” We have received some data from one source which seem to imply a rare earth separation failure, but nothing definite.

So we work with what we have got.

This was the so-called “pilot plant” in Germany:

We would deem this rather a laboratory, not a “pilot plant” mimicking industrial size solvent extraction. But we leave judgement to the eyes of the beholder.

Failed separation?

Looking at what was published one could suspect that the “separation” actually turned out like a split of the lanthanides at the promethium gap:

Unseparated light rare earth up to the promethium gap (La-Ce-Pr-Nd);

The rest of unseparated REE after the promethium gap (Sm-Eu-Gd-Tb-Dy-Ho-Er-Tm-Yb-Lu);

MEAB then somehow managed to chisel some Pr-Nd (“NdPr”) out of the light rare earth rare earth chloride mix.

If so, it would explain the odd term “separate streams of La/Ce, Nd/Pr, Y and HREE chloride fractions.”

Separating yttrium, located elsewhere on the periodic table, should have been a lesser problem.

Note that this part of the me material flow chart does not bear the check-mark the previous steps in the process have.

The chloride produced by MEAB inexplicably is “Pr & Nd oxide” in the above chart. We assume the chart was prepared before the “separation” of the “demo plant” had concluded. Possibly rather hope than fact.

We suspect detrimental co-extraction as well as high impurities and asked MEAB for the analysis result. The company chose not to respond.

Almost 90,000 t of radioactive thorium waste over life of mine

The EURARE study does not contain one single word about the radioactive thorium waste content (“NORM”) of Kvanefjeld.

The ERECON study, however, contained the numbers below.

While the operator is very meticulous about Kvanefjeld’s 0.03% uranium content, we do not see such attention to the substantial radioactive thorium content, which is almost 3 times higher than the uranium content.

At the suggested processing rate of 3 mio t per year and 700 ppm elemental thorium content the operation would turn out 2,390 metric tons as thorium (hydr)oxide per year. At the planned 37 years of operation this would mean a safe, permanent and compliant storage facility for ca. 90,000 t of radioactive waste would be needed. This is rather substantial and it would have required quite a bit of attention.

Did Greenland Minerals plan to put this large quantity of highly concentrated radioactive waste into the planned open tailings storage?

In the Kvanefjeld pilot plant flow chart of Outotec, Finland, thorium seems to end up in the “Residue Storage Facility 2” - whatever that may be at the Greenland site:

Latest announcement

In its latest process-related announcement of 7 October 2020 the company says

Locked cycle flotation test work has been underway at the BTMR laboratories in China through 2020, overseen by rare earth specialists Shenghe Resources Holding Co Ltd (Shenghe).

So the company had changed the service provider and turned to major shareholder Shenghe Resources, China. Even with best effort is was not possible to track down “BTMR” laboratories in China. We assume some mineral research entity in Baotou, China’s center of all things rare earth.

The results announced are:

This means, in terms of the material flow chart above, the following changes occured:

The most significant recovery loss during the EURARE project occured after this step. And it does not really help if the ore input grade inexplicably increases by 15% (~0.2% above the mineral resource assessment) and then the subsequent concentrate grade as a result somewhat unsurprisingly increases 8% over previous assessments.

This announcement also triggered expert questions.

Our take

At this time we see no base for a positive assessment of Kvanefjeld’s feasibility as a potential rare earth resource.

We are very concerned that the company may attempt to be cavalier about the life-of-mine ca. 90,000 t thorium radioactive waste issue.

The company may claim that this waste will be “re-diluted” in millions of tons of other tailings of whatever composition. We can’t see this being likely to happen. Once Pandora’s Box has been opened, it will be costly and hard to close it.

They had a fairytale American childhood - but was radiation slowly killing them?

St Louis, meanwhile, was where uranium was refined and used to help create the atomic bomb as part of the Manhattan Project. After World War Two ended, the chemical was dumped near the creek and left uncovered, allowing waste to seep into the area.

Decades later, federal investigators acknowledged an increased cancer risk for some people who played in the creek as children, but added in their report: "The predicted increases in the number of cancer cases from exposures are small, and no method exists to link a particular cancer with this exposure."

The clean-up of the creek is still ongoing and is not expected to finish until 2038.

"Fifteen people from the street I grew up on have died from rare cancers," she says. "We have neighbourhoods here where every house has been affected by some cancer or some illness. We have streets where you can’t just find a house where a family has not been affected by this."

When Karen’s sister was just 11 years old, doctors discovered that her ovaries were covered in cysts. The same had happened to their neighbour when she was just nine. Karen’s six-year-old granddaughter was born with a mass on her right ovary.

If anyone ever had questions, why the “giving back to nature” of concentrated radioactive waste isn’t exactly among the brightest ideas in human history.

We expect junior rare earth miners to have a valid and compliant concept for safe, permanent and compliant disposal of their radioactive waste. They should not even dare and try insulting investor intelligence by saying “we don’t have any” or “ours is very low.”

Belarus (hilarious!)

Lukashenko Orders Search For Rare Earth Metals In Belarus

The dictator said that this is a "hot topic".

Belarusian dictator Aliaksandr Lukashenka ordered his specialists to find out whether there are rare earth metals in the country. According to him, this is now "the most hot topic", BelTA reports.

Newsweek’s rare earth competence

Map Shows World's 10 Largest Rare Earth Element Reserves

Since Brazil at 21,000 t apparently qualifies for the term “largest” (where did Newsweek get this false number?) , there would be missing:

Myanmar, Laos, Malaysia, Indonesia, Mongolia, Norway, Angola, Nigeria, DR Congo, Burundi, Madagascar, Mozambique, Kyrgyzstan, Norway, to name just a few above 21,000 t not included in this “map.”

By the way: Ukraine is not on the Newsweek map…..

The Critical Minerals Secret Supply Chain Sauce is in the Technology Companies

The tiny, unrecognized, and silent group of workers who engineer the results of solid-state physics and chemical science into mass-produced technologies are mostly just observers of the uneducated and technologically illiterate reporters and politicians who speak about technologies, the creation of which and the operations of which they do not understand.

Therefore, it is not surprising that governmental policymakers do not understand the details of the supply chains necessary to mass-produce rare earth permanent magnet motors because their advisors do not understand the details or intermediate stages of the complex supply chains essential for their mass production.

In a nutshell.

Not yet dead

China’s monthly rare earth raw material imports from Myanmar

Keep reading with a 7-day free trial

Subscribe to The Rare Earth Observer to keep reading this post and get 7 days of free access to the full post archives.